IAC MANUFACTURING (MALAYSIA) SDN.BHD.

At IAC Malaysia, we have both a machine and chemical process factory, and mass aerospace parts production with one stop solution.

IAC Malaysia Machining factory

Overview/Summary/Outline

| Business |

Aircraft parts |

|---|---|

| Address |

Number, 1, Jalan T.U. 50, Taman Perindustrian Tasik Utama, Ayer Keroh, 75450 Melaka, Malaysia. |

| TEL |

+ 606 232 0067 /1067 |

| FAX | + 606 232 3167 |

| Site area | 18,771㎡ |

| Employee | 95 |

| Main Equipment | 5-axis machining center:18 units 4-axis machining center:4 units 3-axis machining center:3 units CMM:3 units |

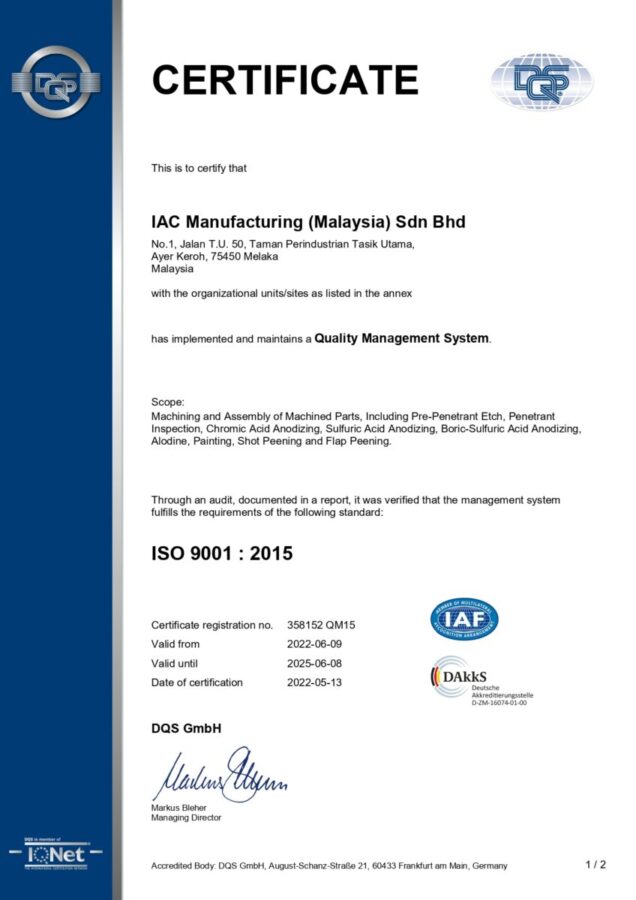

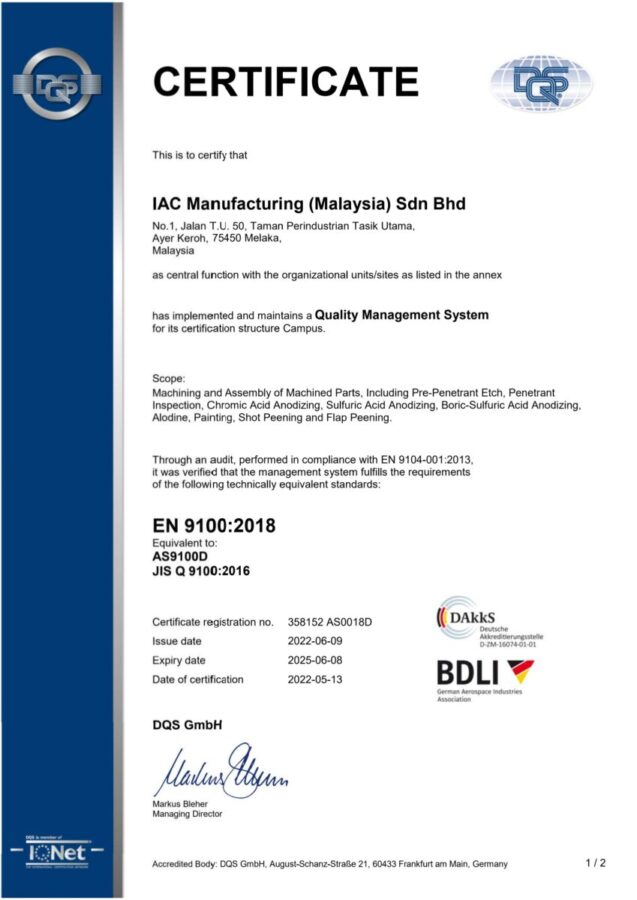

Certification

IAC Malaysia factory acquired EN 9100 (AS 9100/JIS Q 9100)in 2007.

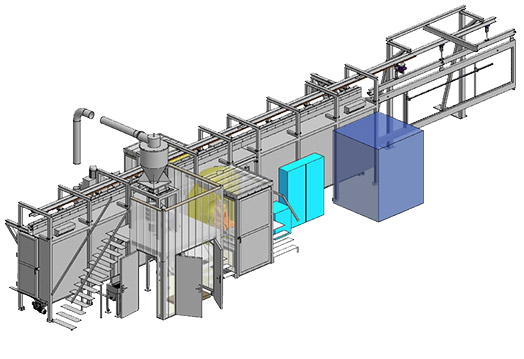

Factory layout

IAC Malaysia Chemical process/Paint factory

company information

| Business | Chemical process/Paint for aircraft parts |

|---|---|

| Address |

Number, 9, Jalan T.U. 45,Taman Perindustrian Tasik Utama, Ayer Keroh, 75450 Melaka, Malaysia. |

| TEL | + 606 232 2062 /072 |

| FAX | + 606 232 2067 |

| Employee |

25 |

| Site area | 2,012㎡ |

| Tank Size |

L5500 x W750 x H1500 mm (L217 x W30 x H59 inch) |

| Certification |

|

Nadcap certification

Nadcap is an international accreditation system for special processes in the aerospace and defense industries, and is operated by the US PO PRI.

The world’s aerospace prime makers(Boeing, Airbus, GE, Rolls Royce, etc.) is attending PRI.

Prime manufactures require their suppliers to obtain Nadcap certification.

* “Special Processes” are processes where the resulting product cannot be easily or economically inspected.

BOEING certification details

Document D1-4426 – Processes for BE10386535

D1-4426 Approval Report updated March 25,2013

Revision HS – effective March 5,2013

| Operation Name | Specification Number |

|---|---|

| Chromic Acid Anodizing – Class 1, 3, 5 |

BAC5019 |

| Boric Acid – Sulfuric Acid Anodizing Class 1, 5 | BAC5632 |

|

Application Corrosion Resistant Finish for Integral Fuel Tanks |

BAC5793 |

| Liquid Penetrant Inspection, Per NAS410 |

BAC5423 BSS7039 |

| Shot Peening, Shot Peening – Self Contained |

BAC5730 BAC5730-2 |

| Salt Spray Testing |

ASTM-B-117 |

Shot Peening

| Maximum Parts Size | T300mm x W1950mm x L5950mm (T12inch x W77inch x L234inch) |

|---|